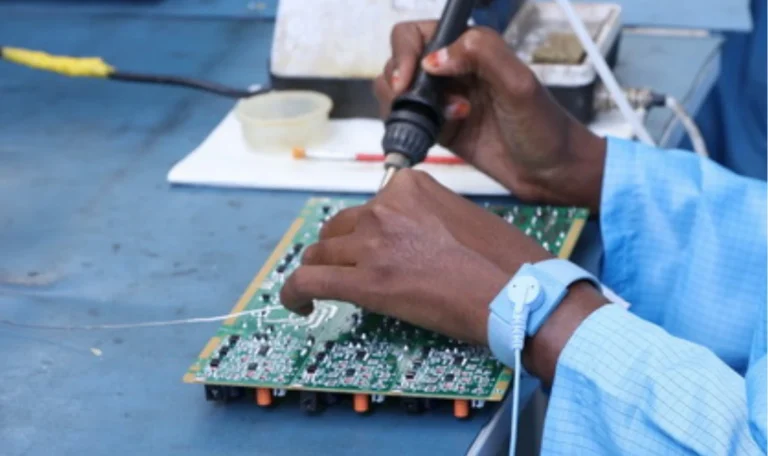

Printed Circuit Boards (PCBs) have become indispensable in modern electronics, serving as the backbone of countless devices across industries like telecom, automotive, medical, and consumer electronics. As we approach 2025, PCB manufacturing is undergoing a significant transformation, driven by advancements in technology and growing demands for innovation, efficiency, and sustainability. This blog delves into the latest trends shaping the future of PCB manufacturing and highlights how these developments are revolutionizing the industry. 1. The Evolution of PCB Manufacturing PCB manufacturing has consistently evolved to accommodate the increasing complexity of electronic devices. The demand for smaller, faster, and more efficient boards has paved the way for advancements in materials, design processes, and assembly techniques. Emerging trends like automation, green manufacturing, and cutting-edge technologies are reshaping the industry, enabling manufacturers to meet the requirements of next-generation devices while addressing challenges such as cost efficiency and sustainability. 2. Trends Shaping the Future of PCB Manufacturing A. Rise of 3D-Printed PCBs 3D printing is revolutionizing PCB manufacturing by enabling intricate designs, faster PCB prototyping, and reduced material wastage. Unlike conventional methods that rely on subtractive processes, 3D printing uses additive techniques to build layers, ensuring precision and efficiency. This technology is particularly beneficial for industries requiring quick prototyping or low-volume production, such as medical devices and aerospace. The flexibility of 3D printing also allows for customized designs, catering to unique project specifications. B. Flexible and Rigid-Flex PCBs Flexible PCBs, made from materials like polyimide, are gaining popularity for their ability to adapt to compact and irregular designs. These boards are lightweight, durable, and eliminate the need for traditional connectors, making them ideal for wearable devices, medical equipment, and foldable electronics. Rigid-flex PCBs, a hybrid of rigid and flexible boards, combine the benefits of both, enabling seamless integration into devices that require flexibility without compromising on functionality. C. High-Density Interconnect (HDI) Technology HDI PCBs are becoming a standard for devices that demand compact designs with enhanced performance. By incorporating microvias, fine traces, and multiple layers, HDI boards support the miniaturization of electronics without sacrificing efficiency. This technology is vital for IoT devices, advanced telecom equipment, and next-generation automotive systems, enabling manufacturers to achieve higher functionality in smaller form factors. D. Green Manufacturing Practices Sustainability is no longer an option but a necessity. The PCB industry is increasingly adopting eco-friendly practices, such as using recyclable materials, reducing energy consumption, and minimizing waste. By integrating green technologies, manufacturers not only comply with environmental regulations but also contribute to a cleaner and more sustainable future. This shift is particularly important for companies looking to enhance their brand image and appeal to eco-conscious customers. 3. Technological Innovations in PCB Assembly Services A. Automation and AI Integration Automation is revolutionizing PCB assembly by improving speed, accuracy, and scalability. Automated assembly lines can handle complex designs with minimal human intervention, reducing errors and production times. AI-powered design tools further enhance this process by optimizing layouts, identifying potential issues, and streamlining production workflows. Predictive maintenance systems also help manufacturers prevent downtime and ensure consistent quality. B. Enhanced Quality Assurance Real-time quality control systems are transforming the way PCBs are manufactured and assembled. Advanced inspection tools, such as Automated Optical Inspection (AOI) and X-ray inspection, ensure that defects are identified and rectified during production. This proactive approach minimizes waste, improves product reliability, and reduces the likelihood of recalls, saving both time and resources. C. Advanced Material Solutions The use of advanced materials, such as high-frequency laminates and thermal management substrates, is addressing the growing demand for PCBs that can withstand extreme conditions. These materials enhance signal integrity, manage heat dissipation, and improve overall performance, making them essential for applications in telecom, automotive, and industrial electronics. 4. Challenges and Opportunities in PCB Manufacturing The advancements in PCB manufacturing are not without challenges. Rising material costs, supply chain disruptions, and the need for skilled labor are significant concerns for the industry. However, these challenges also present opportunities for manufacturers to innovate and adapt. Investing in local production facilities, upskilling the workforce, and adopting agile manufacturing practices can help overcome these hurdles and drive long-term growth. Collaboration with experienced PCB assembly providers can also provide access to the latest technologies and expertise, ensuring a competitive edge in the market. 5. The Road Ahead for PCB Manufacturing As we move towards 2025, the PCB industry is poised for unprecedented growth and innovation. Technologies like 3D printing, flexible PCBs, and automation are setting new benchmarks in efficiency, sustainability, and functionality. For businesses looking to stay ahead of the curve, embracing these advancements is crucial. By partnering with reliable PCB manufacturing and assembly providers, companies can unlock the full potential of these trends and deliver superior products to their customers. Conclusion The future of PCB manufacturing is bright, with innovations driving the industry towards greater efficiency, sustainability, and versatility. By keeping pace with these trends, manufacturers can ensure they remain competitive in an increasingly dynamic market. At Sanjay Technologies, we specialize in providing cutting-edge PCB assembly services tailored to your needs. Whether you’re looking to PCB prototype a new design or scale up production, our expertise and state-of-the-art facilities ensure the highest quality and performance. Contact us today to learn more about how we can help bring your vision to life with industry-leading PCB Assembly solutions.