Ensuring reliability in electronic devices starts with quality control in PCB assembly. As industries like medical devices, aerospace, and automotive demand uncompromised precision, the role of high-quality PCBs becomes even more critical. A single defect in a PCB can lead to significant operational failures, increased costs, and risks to safety. This is why Sanjay Technologies prioritizes excellence in every step of the assembly process, setting a benchmark for quality in PCB manufacturing.

The Importance of Quality Control in PCB Assembly

Quality control is not just an operational necessity—it’s a business imperative.

- Background: In PCB manufacturing, ensuring every component and connection adheres to strict standards prevents malfunctions and enhances product reliability.

- Risks of Poor Quality: Device malfunctions, reduced product lifespan, and even safety hazards. For industries like telecom and defense, where failures are not an option, strict quality measures are critical.

- Significance Across Industries: Quality control underpins the trustworthiness of electronic products, building reputation and ensuring customer satisfaction.

The Sanjay Technologies Approach to Quality Control

At Sanjay Technologies, quality control is a multi-layered process encompassing advanced tools, skilled personnel, and adherence to international standards.

Advanced Inspection Techniques:

We leverage tools like Automated Optical Inspection (AOI), X-ray inspections to detect issues such as solder joint defects, misaligned components, and internal PCB layer problems. These inspections ensure no product leaves the facility with undetected flaws.

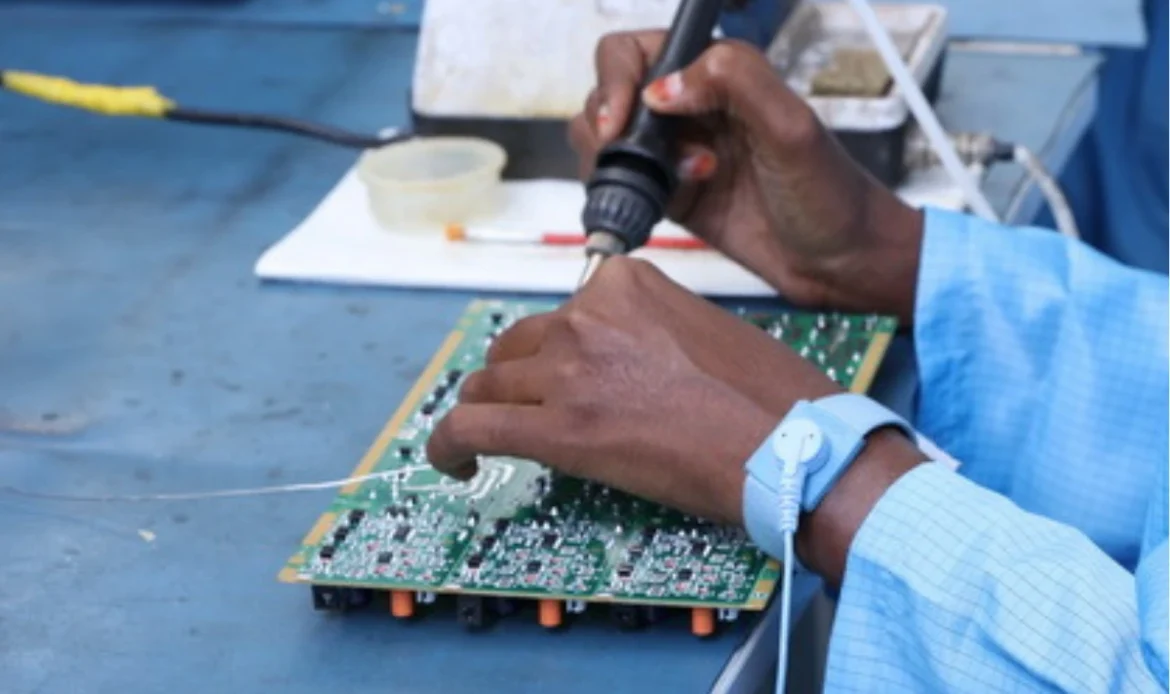

Skilled Workforce:

Our team of certified technicians and engineers meticulously reviews PCBs at every stage. Their expertise guarantees that the highest quality standards are maintained.

Compliance with Industry Standards:

Sanjay Technologies adheres to ISO 9001 and IPC-A-610 certifications, ensuring our products meet global benchmarks for safety, performance, and reliability.

Practical Tips for Ensuring Quality in PCB Assembly

If you’re an entrepreneur in the PCB manufacturing space, here’s how you can prioritize quality:

- Partner with Reputable Manufacturers: Work with experienced providers like Sanjay Technologies, who have proven expertise in delivering high-quality PCBs.

- Invest in Training: Equip your team with the latest knowledge on PCB inspection techniques and global standards.

- Leverage Automation: Use Automation in the production process to enhance precision, reduce errors, and speed up defect detection.

- Regular Audits: Conduct regular reviews to identify gaps in processes and improve quality control measures.

The Benefits of Superior Quality Control

Quality control doesn’t just mitigate risks—it brings tangible benefits to your business:

- Customer Satisfaction: Delivering reliable products fosters trust, ensuring repeat business and long-term loyalty.

- Cost Savings: Detecting and addressing defects early minimizes rework and warranty claims, reducing overall production costs.

- Enhanced Brand Reputation: Consistent quality builds your credibility in competitive industries like oil & gas, telecom, and automotive.

Final Thoughts

Quality control is the cornerstone of excellence in PCB assembly. By prioritizing advanced techniques, skilled personnel, and adherence to standards, Sanjay Technologies exemplifies what it means to deliver reliable, high-performance PCBs. If you’re looking for a trusted partner to help your business achieve quality-driven success, Sanjay Technologies is your solution.